Thermal Spray Coating Services

Thermal Spray Coating Services Specification

- Payment Mode

- Online/Offline

- Finish Type

- Matte/Satin/Shiny

- Coating Material

- Aluminium, Zinc, Copper, Nickel, Chrome, Ceramic, Tungsten Carbide, Molybdenum

- Layer Thickness Range

- 50 to 500 microns

- Service Mode

- Offline

- Application Method

- Flame Spray, Arc Spray, Plasma Spray

- Service Location

- All Over India

- Maintenance Requirement

- Low to Minimal

- Max Workpiece Size

- Up to 12 meters

- Environmental Compliance

- Meets ISO 14001 Standards

- Duration

- 1-12 Months

- Usage/Application

- Industrial

- Adhesion Strength

- Up to 70 MPa

- Surface Preparation Method

- Grit Blasting

- Corrosion Resistance

- High

- Coating Temperature

- Ambient (Non-Heat Distortion)

- Service Type

- Thermal Spray Coating

About Thermal Spray Coating Services

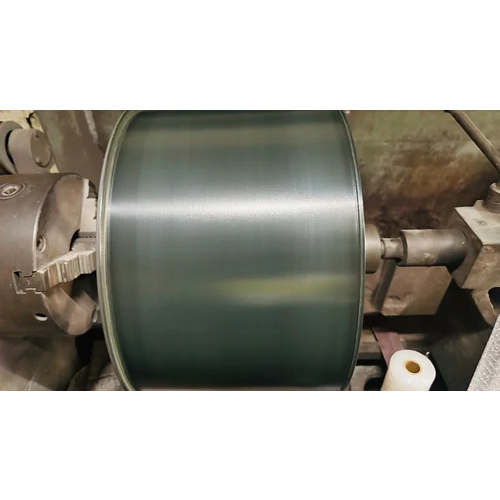

Discover our top-rated Thermal Spray Coating Services, renowned for their uncommon performance and blue-ribbon quality. Utilizing excellent surface preparation through expert grit blasting, we deliver precise coatings from 50 to 500 microns on workpieces up to 12 meters. Available in scarce, limited stock slots, our services cater to demanding industrial needs across India. With high adhesion strengths (up to 70 MPa), exceptional corrosion resistance, and matte/satin/shiny finishes, these coatings are applied using flame, arc, or plasma spray without heat distortion. Maintain your assets with low-maintenance, ISO 14001-compliant, environmentally responsible solutions-available for industrial equipment using metals and ceramics like aluminium, zinc, tungsten carbide, and more.

Applications in Industrial Plants: Where Excellence Meets Versatility

Thermal Spray Coating Services are extensively used in plant applications for surface protection, component refurbishment, and performance enhancement. These coatings serve as protective barriers against wear, corrosion, and environmental damage. They are applied to machinery, pipelines, valves, and structural parts in power plants, petrochemical refineries, manufacturing lines, and heavy engineering industries. The result is an uncommon solution delivering prolonged component life and reduced operational downtime.

Reliable Supply, Certifications, and Swift Distribution

Supplied by a certified manufacturer and service provider, our Thermal Spray Coating Services guarantee consistent quality-measured by ISO 14001 standards. Packaging ensures safe and efficient transportation even for large or sensitive components. With robust supply ability, express shipping options, and prompt proposal amount discussions, we ensure every client across India receives their coatings on time. Service modes and flexible payment methods simplify the delivery process, ensuring a seamless experience from order to execution.

Applications in Industrial Plants: Where Excellence Meets Versatility

Thermal Spray Coating Services are extensively used in plant applications for surface protection, component refurbishment, and performance enhancement. These coatings serve as protective barriers against wear, corrosion, and environmental damage. They are applied to machinery, pipelines, valves, and structural parts in power plants, petrochemical refineries, manufacturing lines, and heavy engineering industries. The result is an uncommon solution delivering prolonged component life and reduced operational downtime.

Reliable Supply, Certifications, and Swift Distribution

Supplied by a certified manufacturer and service provider, our Thermal Spray Coating Services guarantee consistent quality-measured by ISO 14001 standards. Packaging ensures safe and efficient transportation even for large or sensitive components. With robust supply ability, express shipping options, and prompt proposal amount discussions, we ensure every client across India receives their coatings on time. Service modes and flexible payment methods simplify the delivery process, ensuring a seamless experience from order to execution.

FAQ's of Thermal Spray Coating Services:

Q: How does grit blasting contribute to the quality of thermal spray coatings?

A: Grit blasting ensures the workpiece surface is thoroughly cleaned and roughened, optimizing coating adhesion and overall finish. This preparation step is critical for achieving long-lasting, high-performance coatings.Q: What types of coatings are available through this service?

A: We offer coatings using various materials, including aluminium, zinc, copper, nickel, chrome, ceramics, tungsten carbide, and molybdenum, allowing customization based on required protection or unique industrial application needs.Q: When is the optimal period to schedule thermal spray coating services?

A: The best time to schedule these services is during planned maintenance shutdowns or before deploying new equipment, minimizing downtime and ensuring full protective benefits from the outset.Q: Where can these thermal spray coatings be applied?

A: Our coatings are suitable for industrial assets such as machinery, pipes, valves, and structural parts in sectors like power generation, petrochemicals, manufacturing, and heavy engineering, anywhere across India.Q: What is the process for obtaining a proposal amount or service quotation?

A: You can request a proposal amount or quotation by contacting us online or offline. Our team will assess your project requirements and provide a detailed estimate, including service duration and material options.Q: What are the main benefits of using these thermal spray coatings?

A: Key benefits include enhanced corrosion and wear resistance, improved surface properties, low maintenance needs, and adherence to environmental regulations (ISO 14001), resulting in extended equipment lifespan and reduced operational interruptions.

- Minimum Order Quantity

- 1 Unit

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free