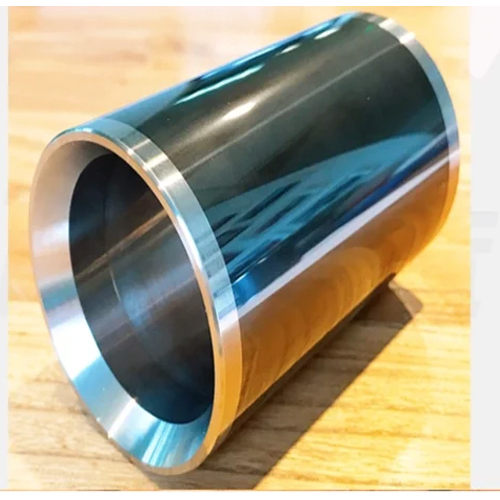

Plunger Ceramic Plasma Coating Services

Plunger Ceramic Plasma Coating Services Specification

- Turnaround Time

- Depends on Quantity and Plunger Size

- Suitable For

- Metal and Alloy Plungers

- Wear Resistance

- Enhanced

- Coating Thickness

- Up to 200 microns

- Quality Standards

- Industry Standard Compliant

- Application Surface

- Plunger

- Temperature Resistance

- High Thermal Resistance

- Customisation

- Available as per requirement

- Surface Finishing

- Smooth

- Coating Material

- Ceramic

- Coating Hardness

- Typically around 1200 HV

- Bond Strength

- Strong Adhesion to Substrate

- Maximum Operating Temperature

- Up to 1300°C

- Corrosion Resistance

- Excellent

- Coating Technology

- Plasma Spray Coating

About Plunger Ceramic Plasma Coating Services

Experience unparalleled protection and performance with our new Plunger Ceramic Plasma Coating Servicesengineered for perfect results. Utilizing advanced plasma spray coating technology, we deliver a smooth, customizable ceramic layer up to 200 microns thick, ideal for both metal and alloy plungers. Expect first-rate resistance to corrosion, wear, and extreme temperatures up to 1300C, all backed by strong adhesion and industry-standard compliance. Enjoy instant checkout for orders and exceptional service from Indias trusted manufacturer and service provider. Custom solutions and fast turnarounds are available for your unique requirements.

Versatile Applications and Commercial Uses

Our Plunger Ceramic Plasma Coating Services are used to enhance the performance and longevity of plungers in high-demand environments. These coatings are perfect for industries such as chemical processing, automotive, oil and gas, and manufacturing. The ceramic coatings strength and durability make them suitable for pumps, injectors, and mechanical systems that encounter abrasion, high temperatures, and corrosive conditions. Choose our solutions for reliability in any commercial or industrial application requiring superior wear resistance.

Packaging, Export Markets, and Payment Proposals

We carefully package ceramic-coated plungers to prevent damage during transit, ensuring each item reaches you in pristine condition. Our export markets include regions across Asia, Europe, and the Middle East, meeting global demands. Payment terms are flexible, tailored to your proposal amount and backed by purchase order agreements. We streamline the transaction for international clients, ensuring efficient service from order placement through to secure shipment and dependable after-sales support.

Versatile Applications and Commercial Uses

Our Plunger Ceramic Plasma Coating Services are used to enhance the performance and longevity of plungers in high-demand environments. These coatings are perfect for industries such as chemical processing, automotive, oil and gas, and manufacturing. The ceramic coatings strength and durability make them suitable for pumps, injectors, and mechanical systems that encounter abrasion, high temperatures, and corrosive conditions. Choose our solutions for reliability in any commercial or industrial application requiring superior wear resistance.

Packaging, Export Markets, and Payment Proposals

We carefully package ceramic-coated plungers to prevent damage during transit, ensuring each item reaches you in pristine condition. Our export markets include regions across Asia, Europe, and the Middle East, meeting global demands. Payment terms are flexible, tailored to your proposal amount and backed by purchase order agreements. We streamline the transaction for international clients, ensuring efficient service from order placement through to secure shipment and dependable after-sales support.

FAQs of Plunger Ceramic Plasma Coating Services:

Q: How does the ceramic plasma coating process enhance plunger performance?

A: The ceramic plasma coating process improves plunger performance by providing a tough, smooth barrier that offers excellent wear, corrosion, and high thermal resistance. This leads to extended plunger service life even in challenging industrial environments.Q: What materials and plungers are suitable for this coating service?

A: Our coating is suitable for metal and alloy plungers, providing strong adhesion and a first-rate finish that meets various operational demands.Q: When can I expect delivery after placing an order?

A: Delivery timelines depend on the quantity and size of plungers ordered. We strive for a rapid turnaround and offer instant checkout for efficient processing of your purchase order.Q: Where are your ceramic plasma coated plungers commonly applied?

A: Our coated plungers are commonly used in pumps, injectors, and high-performance mechanical systems within sectors such as automotive, chemical processing, oil and gas, and manufacturing.Q: What are the main benefits of choosing your customizable coating services?

A: Benefits include a perfect, customizable finish with unparalleled corrosion and wear resistance, strong bonding to the substrate, and compliance with industry standards, ensuring long-term reliability and optimum performance.

- Minimum Order Quantity

- 1 Unit

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry Send SMS

Send SMS