PLASMA COATING

PLASMA COATING Specification

- Density

- Approx. 1.1 g/cm³

- Product Name

- PLASMA COATING

- Chemical Resistance

- Excellent

- Thickness Range

- 0.1 to 10 Microns

- Coating Type

- Plasma Enhanced Chemical Vapour Deposition (PECVD)

- Cure Time

- Within Minutes

- Color

- Transparent

- VOC Content

- Low

- Adhesion Strength

- High

- Surface Finished

- Smooth, Uniform

- Temperature Resistance

- Up to 500°C

- Shelf Life

- 12 Months

- Storage Condition

- Store in Cool, Dry Place

- Usage

- Metal Protection

- Form

- Liquid

- Manufacturer Warranty

- Yes

- Application

- Industrial

- Packaging Size

- 1 Litre, 5 Litre, 20 Litre

About PLASMA COATING

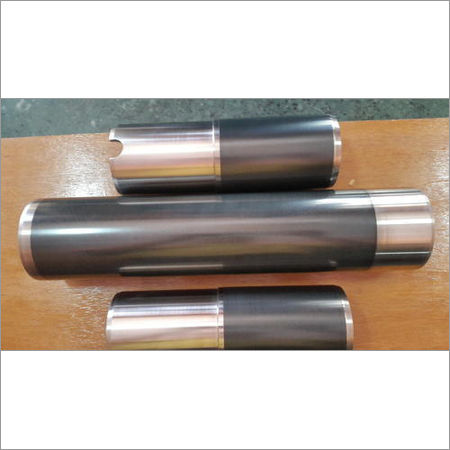

Over the years of dedication, we have been a prestigious service provider of Plasma Spray Processor to our highly valued clients. We have associated with us a team of diligent personnel who have been provided with thorough knowledge training time to time for the updates in the industry. Plasma Spray Processor goes through numerous quality checks to make sure that it stands high on accuracy and quality. Clients can avail this service from us at feasible prices in the market.

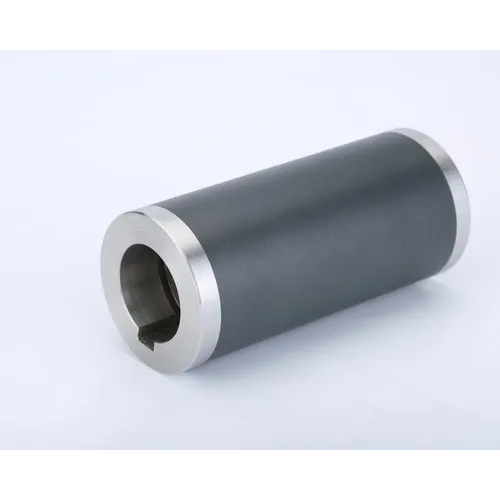

Advanced Surface Protection for Metals

PLASMA COATING leverages advanced PECVD technology to deliver long-lasting protection for industrial metal surfaces. Its smooth, uniform layer guards against harsh environments, chemicals, and extreme temperatures, ensuring sustained performance. The high adhesion and fast cure time mean downtime is minimised, making it ideal for demanding operational settings.

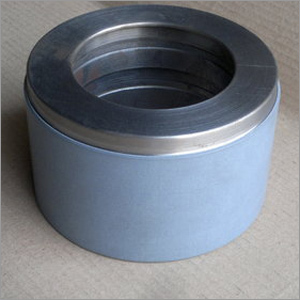

Easy Application and Fast Curing

Designed for user convenience, PLASMA COATING is supplied as a liquid and applies effortlessly to metal surfaces. Cure times are kept to a minimumoften within minutesso your equipment returns to service rapidly. This efficiency reduces labour costs and production delays, while maintaining a consistently high-quality finish.

FAQs of PLASMA COATING:

Q: How is PLASMA COATING applied to metal surfaces?

A: PLASMA COATING is typically applied using standard industrial techniques compatible with liquid coatings, such as spraying or dipping. The plasma-enhanced chemical vapour deposition process ensures the coating forms a smooth, uniform, and highly adhesive layer.Q: What are the primary benefits of using PLASMA COATING?

A: The main advantages include excellent chemical resistance, high adhesion strength, and temperature resilience up to 500C. Its rapid cure time, low VOC content, and clear finish make it ideal for protective applications without altering the appearance of metal surfaces.Q: When should PLASMA COATING be used in an industrial setting?

A: Use PLASMA COATING when metal protection from chemicals, thermal stress, or abrasion is required. Its especially beneficial in environments demanding quick turnaround and superior protective performance.Q: Where should PLASMA COATING be stored for maximum shelf life?

A: For optimal results, store PLASMA COATING in a cool, dry place, away from direct sunlight and humidity. This ensures the product maintains its effectiveness throughout its 12-month shelf life.Q: What is the typical process and cure time for PLASMA COATING?

A: After cleaning and preparing the metal surface, PLASMA COATING is applied and typically cures within minutes. This rapid process allows for swift equipment turnaround and high productivity.Q: How does PLASMA COATING perform against harsh chemicals and extreme temperatures?

A: PLASMA COATING offers excellent chemical resistance and endures temperatures up to 500C, making it suitable for demanding industrial applications where long-term durability is essential.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry Send SMS

Send SMS