CERAMIC COATING

CERAMIC COATING Specification

- Curing Time

- 24 hours

- Form

- Liquid

- Coating Thickness

- 5-10 microns per application

- Water Contact Angle

- >105° (hydrophobic)

- PH Value

- 7-8 (Neutral)

- Packaging Size

- 500 ml, 1 L, 5 L, 20 L

- Chemical Resistance

- Highly resistant to acids, alkalis, and solvents

- Temperature Resistance

- Up to 800°C

- VOC Content

- Low

- Usage

- Protects surfaces by forming a durable, glossy, and water-repellent layer

- Storage Conditions

- Store in a cool, dry place away from direct sunlight

- Abrasion Resistance

- Excellent

- Appearance

- Transparent

- Shelf Life

- 24 months

- Product Name

- CERAMIC COATING

- Bonding Strength

- High adhesion to multiple surfaces

- Suitable Surface

- Metal, glass, ceramic, plastic, automotive parts

- Application Method

- Spray or Brush

- Toxicity

- Non-toxic once cured

About CERAMIC COATING

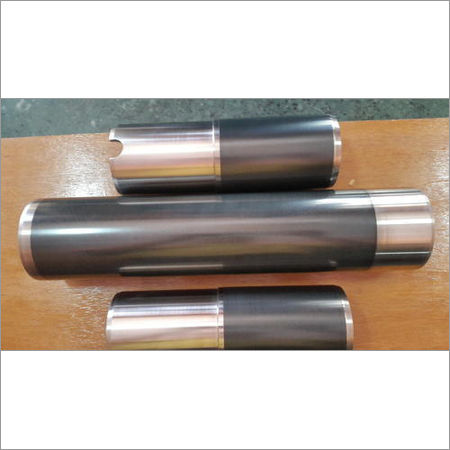

We are a well known provider of Spray Met Services to our highly valued clients. It is used in various industrial sectors. High grade equipment and consumables are used for rendering these services as per the industrial prevailing standards. Spray Met Services have gained us huge appreciation from our clients for their finishing and quality in the form of high rising demands among that of our competitors. The offered services can be availed from us at highly cost- effective prices.

Superior Protection with Lasting Performance

CERAMIC COATING offers exceptional surface protection for industrial and domestic applications. Its advanced formula resists harsh chemicals, abrasion, and extreme temperatures, providing a glossy, hydrophobic finish that repels water and enhances durability. With high bonding strength, it adheres firmly to multiple surfaces including metals, glass, ceramics, and automotive parts, extending the lifespan and maintaining the appearance of coated items.

Simple and Versatile Application Process

This coating is user-friendly, designed for application via spray or brush. Each layer is 5-10 microns thick, ensuring comprehensive coverage without excessive buildup. It cures within 24 hours under normal conditions, making it convenient for quick turnarounds. Available in various pack sizes, its suitable for both small projects and large-scale usage.

FAQs of CERAMIC COATING:

Q: How do I properly apply CERAMIC COATING to a surface?

A: Clean and dry the surface thoroughly. Apply CERAMIC COATING using a spray or brush in an even layer (5-10 microns thick). Allow the coating to cure for 24 hours for optimal bonding and protection.Q: What types of surfaces are suitable for CERAMIC COATING?

A: The product is compatible with metal, glass, ceramic, plastic, and automotive parts, providing excellent adhesion and protective benefits across a range of substrates.Q: When should I reapply CERAMIC COATING for continued protection?

A: While the coating offers lasting durability, periodic inspection based on the exposure and use of the coated surface is recommended. Reapplication can be considered if signs of wear are observed after heavy or abrasive use.Q: Where should I store CERAMIC COATING to maintain its shelf life?

A: Store the product in a cool, dry place away from direct sunlight. Proper storage ensures its effectiveness for up to 24 months.Q: What are the main benefits of using CERAMIC COATING?

A: It provides a transparent, glossy, hydrophobic layer with high temperature and chemical resistance, excellent abrasion protection, and strong adhesion, thereby significantly extending the life and appearance of coated surfaces.Q: Is CERAMIC COATING safe to use and environmentally friendly?

A: Yes, it is low in VOC content and becomes non-toxic once fully cured, making it safe for users and environmentally conscious installations.Q: How does the curing process of CERAMIC COATING work?

A: The coating requires 24 hours to cure after application. During this time, it forms a robust bond to the surface, optimizing its durability, hydrophobicity, and protective qualities.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry Send SMS

Send SMS